Tomorrow

More operating days at BR2

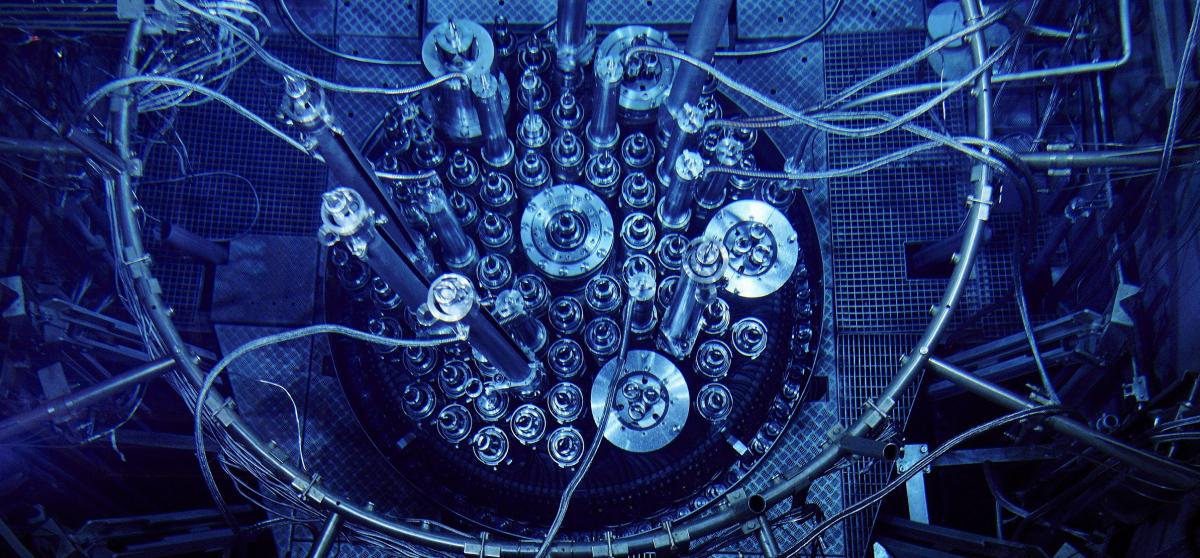

More than ever before, the medical sector can rely on BR2

SCK CEN increases availability of the research reactor from 160 to 210 days

The number of cancer patients continues to increase year by year, which means that the need for medical radioisotopes is also growing. “A continuous supply is crucial,” says Steven Van Dyck, director of the reactor at SCK CEN. In order to guarantee this supply, SCK CEN has decided to increase the number of operating days for the BR2 research reactor from 160 to 210 per year.

In 2016, the scientific and medical world was relieved when the BR2 research reactor was successfully restarted after a complete overhaul. The BR2 was ready for at least another decade of ambitious projects. “Thanks to this full refurbishment, we are technically able to achieve even greater efficiency,” it was described after the completion. SCK CEN immediately put these words into action. In 2019, the research centre made all the necessary preparations in order to increase the number of operating days from 160 to 210. The motivation? The growing international demand for radioisotopes for medical imaging and the treatment of cancer.

“It’s a race against the clock to get medical radioisotopes to the patient in time. A continuous supply is

therefore crucial.”

Change of focus

Medical radioisotopes currently account for two thirds of the irradiation channels at BR2. It was different in the past. “Previously, the emphasis was placed on research focusing on materials, whereas medical radioisotopes were a by-product,” explains Van Dyck.

Is this the end of the line for all other applications? “No,” says Van Dyck emphatically. “The BR2 research reactor is multi-purpose. It is a versatile and flexible installation that can combine several tasks at the same time. We can use the reactor to produce medical and industrial radioisotopes, while at the same time, we can produce high-quality (doped silicon) semi-conductors, and conduct research on materials. In 2019, for example, we successfully completed a multi-year irradiation campaign. By doing this, we brought ITER, the international fusion test reactor at the French research centre in Cadarache, one step closer to its goal of demonstrating the technical and scientific feasibility of nuclear fusion.”

“At the same time, demand for these types of irradiations will only increase in the future. Especially now, since in 2018 the curtain fell on the Halden research reactor in Norway after over 60 years of good and loyal service. This reactor was used for experimental research on fuel and materials.”

A race against the clock

“There are only a handful of medical radioisotope producers in the world. The OSIRIS reactor in France closed its doors at the end of 2015, followed by NRU in Canada in late 2016. There are now only six producers that are left to cover the worldwide demand. And this demand is increasing year by year. This underscores the need for our BR2 research reactor to be available,” explains Steven Van Dyck, director of the reactor. “In addition, we cannot build up stocks, as is the case for hypodermic needle production lines, for example. It’s a race against the clock to get medical radioisotopes to the patient in time. A continuous supply is crucial.”

With this increased availability, SCK CEN is already making a vital contribution to this continuous supply, but the research centre has made an extra effort by increasing its irradiation capacity. “We have equipped an additional reactor channel for the production of diagnostic radioisotopes and doubled our production capacity for therapeutic radioisotopes,” explains Van Dyck.

Which radioisotopes are rolling off the proverbial production line? “The majority are reserved for the production of molybdenum-99, the most important diagnostic radioisotope. Every year, almost seven million examinations can take place thanks to these radioisotopes produced in Belgium. We also produce radioisotopes for the development of targeted cancer treatments. Take lutetium-177, for example. This radioisotope is promising for the treatment of prostate cancer, which is responsible for 90,000 deaths per year in Europe. Or one of the terbium isotopes, which is also known at CERN MEDICIS as the “Swiss Army Knife” of nuclear medicine.”

Anyone can provide a supply that lasts five years. The new diesel generators must also continue to function after operation. We are preparing for the future.

More jobs

In order to be able to offer the scheduled number of operating days, SCK CEN increased the number of operating cycles of the reactor and extended their duration. Van Dyck: “We now operate for 4-5 weeks at a time, whereas we were previously accustomed to operating periods lasting three weeks. In order to ensure that this operation is successful, we recruited 25 employees. These employees are given in-depth training on how to complete each task perfectly. They have to be in perfect harmony with each other.”

Due to the new operating regime, the shutdown time, the period when the reactor is not running, is shorter. This has an impact on the planning of inspections, for example. “Everything is meticulously planned so that all the statutory audits and regular maintenance can be conducted. We attach great importance to these checks. Safety is, and will remain, a top priority.”

The emergency system is divided into two trains. If one train breaks down, we have another in place as a backup: an emergency solution for an emergency solution.

The three Y’s of BR2

Familiarity, availability and reliability. BR2 is a major supplier of medical radioisotopes all over the world. From 2020, the reactor will be more available than ever before. In order to increase its reliability, SCK CEN has replaced the emergency generators. The emergency generators keep the BR2 power grids running in the event of a power failure. “If this type of power failure occurs, the reactor will shut down unexpectedly. An unscheduled shutdown causes us to lose two operating days. This amounts to 1% on an annual basis,” explains Karel Sebrechts who initiated the construction project. “When you know that 7 million medical examinations take place every year thanks to molybdenum- 99 produced in Belgium, then it is clear that an unscheduled shutdown would affect quite a few patients. The old diesel emergency generators had been in service for over 50 years. We could no longer trust them blindly, so it was time to replace them.”

In the old system, three flywheels were continuously turning at 1000 revolutions per minute. The wheels were mechanically linked to diesel generators. As soon as the grid failed, they would start the diesel generators. Project engineer Bob Derboven: “In the new design, we have disconnected both of them. Six intelligent wheels idle in a vacuum at 10,000 revolutions per minute. The flywheels absorb a voltage drop, while the diesel generators, in parallel, start-up electrically. After they start-up, they take over the work of the flywheels. The emergency system is also divided into two trains. If one train breaks down, we have another one in place as a backup. You could call it an emergency solution for an emergency solution.” SCK CEN has constructed a new building to house the emergency generators.

Ready for the future

The project leaders have also developed a safety net for a wide range of incidents. What if a fire is reported? Or if an earthquake causes the site to shake? Bob Derboven, project engineer: “The building is designed to resist earthquakes. In addition, it is divided into different zones. This means that we can keep a fire “sealed off” in a room. In this way, the other rooms remain intact and we can guarantee the operational reliability of BR2.”

Modularity is at the heart of the entire concept. Karel Sebrechts: “Anyone can provide a system that will last five years. The time horizon is not clear for BR2. BR2 will currently be operated until 2026, but we have submitted a safety dossier to extend this period to 2036. There will also need to be emergency response groups for certain functions, regardless of operation. It is therefore important that we can easily extend our modules and replace parts. Our vision for the future goes beyond operation - this is what makes this installation unique. We are preparing for the future.”

I like to call BR2 an important hub for our social relevance. The numerous ways in which our research reactor is used to irradiate materials with neutrons illustrate this clearly, but nowhere as directly as in its role as an indispensable supplier of medical radioisotopes. During each operating cycle, we provide the necessary raw materials for the diagnosis of cancer in at least 1 million patients and for the therapeutic treatment of more than 3,000 cancer patients. The social relevance of BR2, and by extension, all research lines of our national nuclear research institute, is something we Belgians can be proud of.

— Sven Van den Berghe (Nuclear Materials Science)