2050

Nuclear fusion

Nuclear fusion: the sun in a box

SCK CEN is testing structural materials for a nuclear fusion reactor

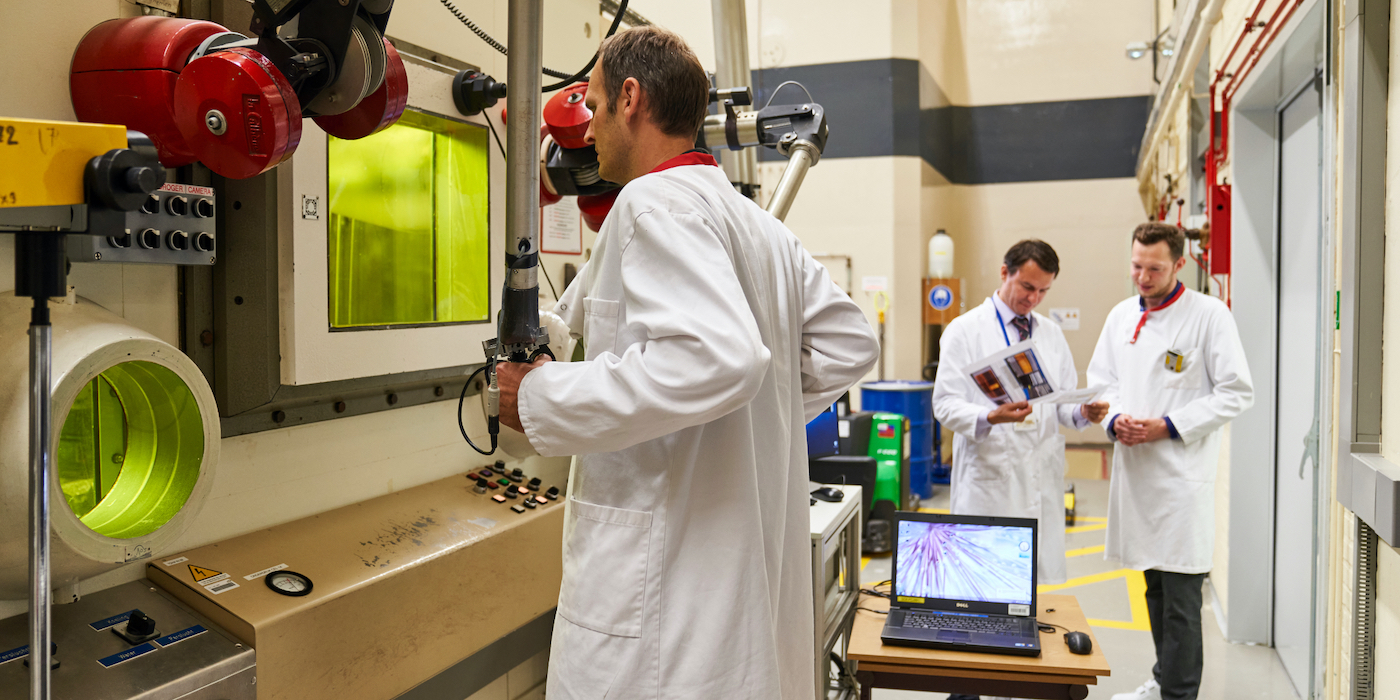

For two years, SCK CEN has been testing structural materials for ITER (international thermonuclear experimental reactor) at its BR2 research reactor. The materials have been exposed to a high neutron flux at up to 1200°C. In 2019, the irradiation campaign was completed and the fusion test reactor at the French research centre at Cadarache moved closer to its goal of demonstrating the technical and scientific feasibility of nuclear fusion. “Never before in the history of SCK CEN have we achieved such extreme conditions,” explains project coordinator, Dmitry Terentyev.

The Sun on Earth. A Star in a Jar. Many different nicknames are used when referring to nuclear fusion, the technique that imitates how energy is generated by the sun. In practical terms, it involves the collision of two atomic hydrogen nuclei which fuse together to form a heavier atomic nucleus (helium). Nuclear fusion could provide an almost unlimited quantity of energy without any greenhouse gas emissions. This is good news when it comes to combating climate change. This technique would also produce far less long-lived radioactive waste than “conventional” nuclear energy.

It will probably take a while longer for a working nuclear fusion installation. At the French research centre at Cadarache, SCK CEN is working with an international team of scientists on the ITER international fusion test reactor. The ITER project aims to demonstrate the scientific and technical feasibility of nuclear fusion as a usable energy source for the future. In 2050, ITER will be replaced by DEMO, a prototype industrial nuclear fusion reactor. That prototype should demonstrate the feasibility for commercial production of electricity.

Radiation-resistant materials

The technical and practical challenges of nuclear fusion are significant. One of the most complex points of operation is the effect of radiation on the equipment, robotics and structural materials of a reactor. In this context, last year, scientists at SCK CEN completed a multi-year irradiation campaign at the BR2 research reactor.

“During the campaign, we qualified the materials that will be used in the fusion reactor. This included materials for the “first wall”, which is directly exposed to the plasma”, explains nuclear fusion expert Dmitry Terentyev. “For two years, we have exposed the materials to a high neutron flux at up to 1200°C. In order to imitate the fusion conditions as closely as possible, we developed the HTHF (High Temperature High Flux) irradiation device. Never before in the history of SCK CEN have we tested structural materials under such extreme conditions. As part of the next stage, the scientists will map the thermal, mechanical and micro-mechanical properties of the irradiated materials. In order to achieve this, SCK CEN is working with research institutes from Germany, Italy, Switzerland and Greece.

Choosing a supplier

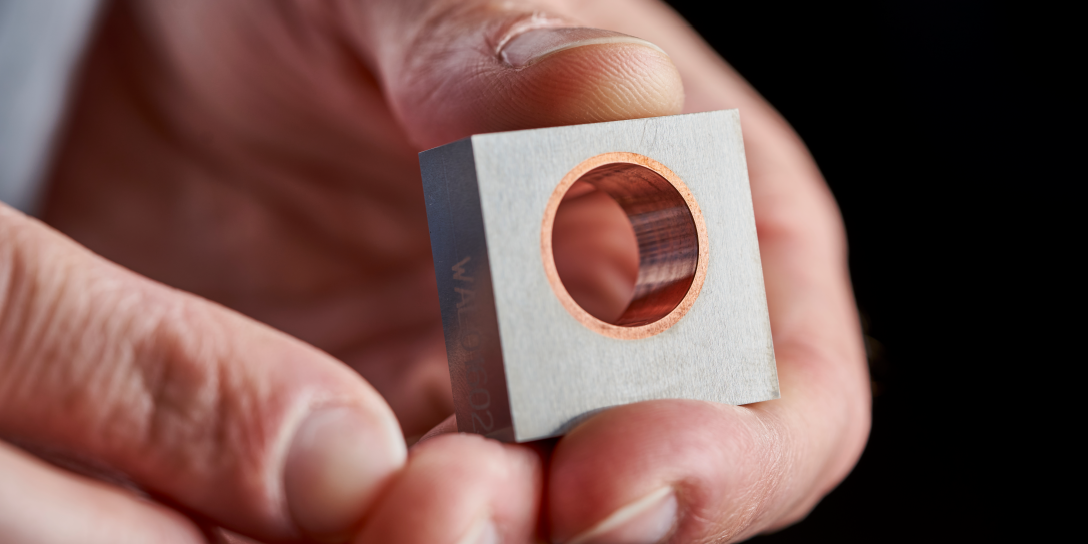

For the irradiation campaign, the structural materials remained in the BR2 research reactor for two years. “This was the minimum length of time needed to imitate the full life cycle of materials in ITER,” says Terentyev. “We mainly studied the possibilities of tungsten, steel and copper. The tungsten in ITER has to provide shielding for the divertor, which is the component that removes heat and cinders from the fusion reactor so that the plasma is not contaminated. The temperatures will be at their highest in the divertor. The outer shell of the divertor is water-cooled and made from tungsten. The inner pipe, through which the water passes, is made from copper. The steel has to support the copper and tungsten structure.”

The base materials for the fusion test reactor have already been selected. SCK CEN is now assessing materials provided by different suppliers. “How the tungsten, steel or copper reacts with the radiation can vary from one supplier to another,” explains Terentyev. “It depends, for example, on the composition of the material, the production process and the installations used. During 2020 and 2021, SCK CEN will analyse any damage and the ageing process of the irradiated materials.”

For two years, we have simulated the effects of nuclear fusion on structural materials. Never before have we achieved such extreme conditions.

Higher TRL level

Completing the irradiation campaign is another step towards the realization of ITER. “We are increasing the TRL level again”, says Dmitry Terentyev proudly. TRL stands for Technology Readiness Level and refers to the level of development for new technologies. The scale consists of 9 levels - from level 1 (research) to level 9 (introduction on the market). “We are currently at level 4 for tungsten and level 5 for steel. For copper, unexpected material embrittlement occurred. We will therefore have to adjust the design in order to progress to the next TRL level.”

The ITER nuclear fusion is a part of the EUROfusion project, a H2020 partnership between Euratom, European Union countries, as well as, Switzerland and Ukraine. For the next stage of the research, SCK CEN, in collaboration with international partners, is developing a new irradiation device in order to test the structural materials used in ITER fuel cells. Therefore, SCK CEN will continue to expand its irradiation capacities at the BR2 research reactor in order to meet the needs of nuclear fusion research.

Compare large-scale projects such as MYRRHA or ITER with the climb of Mount Everest. The summit is the ultimate goal, but the direct path to it is much too steep. That's why we take the alternative, somewhat longer route: one with several approach roads so that we can involve young scientists and celebrate intermediate successes. This creates team spirit and motivation.

— Hamid Aït Abderrahim (Deputy Director General and Director of MYRRHA)